This month wraps the 4th season of Analog Explorer Podcast as we sit down with R.T. Custer, CEO and founder of Vortic Watches.

Analog Explorer Supporters

As a valued supporter, this month, I have something a little special— a full video episode. Thank you again so much for your continued support for such a full season of the Analog Explorer this year!

🇺🇸 America Wasn’t Assembled; It Was Built.

Vortic Watches, proudly based in Colorado, has carved out a unique niche by restoring and preserving vintage American timepieces while also promoting the future of modern American watchmaking and manufacturing. In this episode, R.T. takes us through the past decade and Vortic’s journey, from their early use of 3D printing to their legal fight defending artisanship and upcycling against the major Swiss conglomerate Swatch (Hamilton) in court. We also explore the exciting creation of the Colorado Watch Company in partnership with Fine Timepiece Solutions (FTS).

Passion for America and Storytelling

Vortic Watches is more than just a company—it’s a movement built on creativity, American manufacturing, upcycling, and history preservation. Many of us in the #watchfam believe that every watch tells a story. But unlike most brands that craft a story for marketing, Vortic leans into authentic history. Many of Vortic’s clients bring their own familial and historical pocket watches to the company, entrusting them to encase these family heirlooms to be worn contemporarily so their stories can be retold. It’s this deep connection to history, paired with an unyielding passion for American manufacturing, that makes each Vortic less about the object they create and more about where it has been—and more importantly, where it’s going.

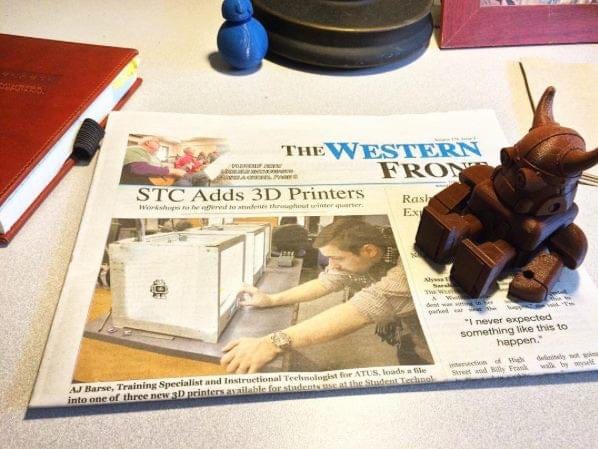

3D Printing and Kickstarter Roosts

On this episode, R.T. reflects on the company’s humble beginnings, which started as a school project at Penn State. Back then, R.T. and his co-founder Tyler took their innovative business plan from the classroom to their creative space- the golfing green. Their breakthrough came through 3D printing technology, which allowed them to rethink what American manufacturing could look like, converting vintage American pocket watches into modern wristwatches. Rebuilding American manufacturing was the guiding principle that became Vortic’s ethos of innovation and preservation. Many of us in the #watchfam forget that America was once the global leader in precision watchmaking, on par with how Swiss timekeeping is known today. American-made railroad-grade pocket watches were some of the most sought-after timepieces during the steam train boom and Industrial Revolution era.

In today’s age of global manufacturing and marketing, Vortic stands out with its motto, “America wasn’t assembled; it was built.” In watchmaking, Vortic is on track to make the most American-made watches (to scale) since those early pocket watch days.

“…why let the Swiss have all the fun.”

- RT Custer (Analog Explore Ep 26)

I remember when Vortic first came on the #watchfam scene ten years ago. As an academic researching the “makerspace movement,” I came across R.T. and Vortic’s story in its early days. Back then, I was teaching 3D printing workshops and often cited Vortic as a case example to my students of what 3D printing can do beyond the classroom.

Whether you’re a watch enthusiast, a lover of American history, or someone who appreciates American manufacturing or craftsmanship, this episode offers a deep dive into the passion and vision that fuels Vortic Watches—and now the Colorado Watch Company.

Analog Explorer ™ is a reader-supported publication. To receive new posts and support my work, consider becoming a free or paid subscriber.

Analog Explorer Episode 26 | “America wasn’t assembled, it was built”

The Lawsuit: Battling for Craftsmanship and Upcycling

One of the defining moments in Vortic’s journey was their legal battle against Swatch, a major Swiss conglomerate. Swatch sued Vortic over trademark issues related to Vortic’s use of antique Hamilton watch dials in their restorations. R.T. opens up about the emotional and financial toll of the lawsuit, which struck at the heart of Vortic’s mission: preserving historical timepieces and transforming them into something new. Vortic stood firm, defending not only their right to restore and repurpose but also championing the larger cause of artisanship and upcycling.

This victory wasn’t just for Vortic—it set a legal precedent for all American artisans everywhere, protecting the right to repurpose and breathe new life into vintage goods. It’s a triumph that ensures creativity and craftsmanship can continue to thrive in a world increasingly dominated by mass (global) production.

Jack Ryan and Vortic Watches: On-Screen Spotting

For fans of the Amazon Prime series Jack Ryan, you might have caught a glimpse of Vortic Watches on the wrists of actors in the show. R.T. shares the thrill of seeing their watches on-screen. More than just a moment in the spotlight, this recognition is a testament to the growing appreciation for Vortic’s craftsmanship. In many ways, the relentless pursuit of truth by the character Jack Ryan mirrors Vortic’s mission to preserve American history, one watch at a time.

What’s Next: Colorado Watch Company and FTS Partnership

Looking to the future, RT discusses Vortic’s exciting collaboration with Fine Timepiece Solutions (FTS), an Arizona-based company specializing in American movement manufacturing. Together, they are launching the Colorado Watch Company, which promises to produce the most American-made watch at scale in the United States. Unlike Vortic’s focus on restoring vintage timepieces, the Colorado Watch Company will produce fully new watches using American movements and materials.

This partnership represents a monumental step forward in domestic watchmaking. With FTS’s expertise in precision movements, the Colorado Watch Company is poised to deliver high-quality, fully American-made watches that will be accessible to a broader audience without compromising craftsmanship. R.T.’s mission is to make Colorado Watch Co. 100% Made in America, by improving on their manufacturing 1% every year. And I believe, by the time our kids are old enough to drive, he might be able to achieve it! 🇺🇸